INTRODUCTION

Plant operations trainee is required to become familiar with the general plant layout, have a basic knowledge of plant equipment and of the instrumentation involved in the automation of the plant. A fourth class candidate should be able to recognize and identify various instrumentation components involved in plant processes.

There are many ways of categorizing instrumentation. At an introductory level, a trainee should be aware that the purposes of instruments can be broadly organized into two groups: those which control a process, and those which simply give us information and/or safeguard the condition of the process. The first group includes the components of a control loop; the second group includes indicators, alarms, and shutdown devices. In this module we will survey these two groups.

CONTROL LOOPS

Open and Closed Loops

There are many ways to implement control of a process using mechanical, pneumatic, electrical, analog, and digital techniques. Regardless of the method used, the basic theory is similar.

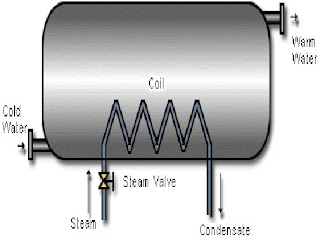

A simple example of manual control is illustrated in Fig. 1, where steam is used to maintain the temperature of water close to the desired value.

Figure 1

Manual Control Water Heating System

Cold water enters at the left end of the heat exchanger, and hot water is discharged at the right. A manually operated valve is used to control the steam flow into the heater. If all the variables such as water flow, steam flow, and steam quality are constant, the outlet temperature of the water could be maintained at the desired value simply by opening the steam valve the correct amount and leaving it there. However, if the temperature of the incoming cold water changes, or if the quantity of heated water that is required varies, the outlet temperature would deviate from the desired value unless the opening of the steam valve was manually readjusted.

If the flow of cold water increased due to an increase in pump discharge pressure, or if the pressure of the steam decreased, the result would be a decrease in the temperature of the water at the outlet. To compensate for such disturbances in the water heating process, and to maintain the desired water temperature that is indicated on the thermometer, the operator must open the steam valve further to supply the correct energy input to the heat exchanger.

This type of control system is called manual or open loop. There is no other way to change the control valve opening except manually, because no intelligence about the process variable (the variable being controlled) ever automatically reaches the control valve to change its position. The operator must check the thermometer frequently to see if there is any error or deviation (the difference between the desired and actual value of the process variable in temperature) and to see whether the error is moving in an increasing or decreasing direction.

A manual, or open loop, process control system similar to this one needs constant attention. The desired value of the process variable is difficult to maintain. To overcome many control problems, automatic or closed loop control systems are used. An example of an elementary automatic control system is shown in Fig. 2.

1. Process

A process may be defined as a manufacturing operation which uses energy to produce a change in a material, or to produce another energy conversion. The process may take many forms. It may be the maintenance of water level in a boiler or tank, the control of the flow rate of various liquids and gases, or the maintenance of pressure in a vessel.

2. Controlled or Process Variable

The process variable may be energy or material which is to be adjusted to a definite value. Examples of process variables are pressure, level, flow, temperature, and composition.

3. Set Point

Set point is the desired value of the process variable. In Fig. 1, the desired temperature of water from the heater may be 80ºC. Or, for example, a boiler operator would want to maintain pressure as close as possible to some desired value.

4. Error

Error is the difference between the actual value of the controlled variable and the set point. It is the margin by which an automatic controller misses the desired value. Sometimes error is also called the deviation.

5. Sensing or Measuring Element

This name refers to the device that measures the value of a controlled variable. Sensing elements are used to convert a measurement, such as pressure, temperature, or flow, into a movement or signal that can be used for transmission to a controller, recorder, or indicator. They are also called detectors or sensors.

6. Disturbance

The process may be subjected to a disturbance or upset of some sort; otherwise, there would be no need for a control system. A disturbance in a process may take the form of changing flow rate, a variation in temperature or pressure, or a number of other factors.

7. Manipulated Variable

This is the variable which is adjusted to bring the process variable back to the desired value or set point. In most cases the manipulated variable is some form of flow. In the situation shown in Fig. 1, an operator must adjust the control valve manually to permit adequate steam flow (the manipulated variable) to the heat exchanger, so the water temperature will be as close as possible to the desired temperature.

8. Transmitter

In some control systems, the sensing element may be located in a controller close to the process. However, in many larger installations the controller may be in a control room located far from the process, so it is not feasible to locate the sensing element with the controller. In this case, the sensing element will be located where the process variable can be monitored, and its proportional electric or pneumatic output will be converted to a longer range signal by a transmitter. This signal is transmitted over fairly long distances to the controller in the control room, as shown in Fig. 2. An operator can supervise the operation of many plant processes from this remote location and can manually take over control of a process if a malfunction takes place.

9. Indicators and Recorders

Indicators such as thermometers and pressure gages can usually be located close to their respective processes, and in the control room, to instantly show the values of different variables to the operators and maintenance personnel.

Recorders normally consist of one or more pen mechanisms, whose instantaneous position indicates the value of the variable (pressure, level, or flow) being monitored or recorded on a chart for future reference. When a recorder is placed near the process or point of measurement, the sensing element may be located directly in the recorder. If the recorder is in a remote location, the respective transmitter output signal is used to position the pen on a recorder, as shown in Fig. 2.

A recorder pen continuously marks the value of a monitored variable on a chart that is moved at a constant speed. Since the time is printed on the chart, an operator can see the instantaneous value of the variable and how it changed with time. An indicator and/or recorder may also be built directly into a controller for simultaneous observation and control.

10. Controller

The controller is a very important component of an automatic control system, as it is the instrument that responds to the value of the process variable (the temperature, in Fig. 2) and positions the control valve. It continuously compares the value of the process variable (usually a transmitter output signal) with the set point setting.

The set point signal may be adjusted manually by an operator, by a computer, or by another instrument. If the process variable deviates from the set point, the controller output will take corrective action by changing the magnitude of its output signal to the final control element, such as a control valve. Repositioning of the control valve in Fig. 2 will alter the rate of flow of the manipulated variable (steam flow) to bring the process variable (temperature) back toward the set point. Controllers are normally equipped with an automatic/manual transfer station, which allows an operator to switch the process from automatic to manual, or vice versa, with minimum delay.

11. Final Control Element

This is the component of a control system that adjusts the value of the manipulated variable. A control valve may be used to adjust fuel flow to a boiler combustion system, while a damper may be used to provide the correct combustion air supply.

Automatic Process Control Principles

The manually controlled water heating system in Fig. 1 has been converted into one that is automatically controlled in Fig. 2. A sensing element, transmitter, and a controller are placed in the form of a control loop between the product outlet (hot water) and the final control element (control valve). The opening of this control valve can be varied by a change in air pressure from the controller that is technically called a pneumatic signal.

During normal operation, the control valve permits the required amount of steam flow into the heat exchanger to raise the water from its inlet to the final desired temperature. If the final or discharge temperature of the water should drop, the temperature sensing element will sense this change and will produce a proportional change in output from the transmitter. The transmitter output, representing the value of the process variable (temperature), is compared with the set point signal in the controller. Since the temperature of the water has dropped, there will be an increased difference between the two signals.

The controller will respond to this greater deviation or error by opening the control valve further to increase the steam flow and thus, the temperature of the hot water. If the temperature of the water from the heater should increase, the sensing element will sense this change and cause a proportional change in the transmitter output. This will cause the controller output to close the control valve further and reduce the heat energy input to the heat exchanger.

Comparing the open loop or manual control system in Fig. 1 with the automatic or closed loop system in Fig. 2, it can be seen that the open loop system has no way of changing the position of the control valve because no intelligence about the process variable (temperature in this example) ever automatically reaches the control valve to change its position. An operator must notice changes in temperature on the thermometer and adjust the flow of steam to the heater. In the closed loop system in Fig. 2, the value of the process variable is fed back to the controller constantly, so corrective action can be made more accurately and quickly to keep the process closer to the desired value.

SIGNAL TRANSMISSION

Signals or information related to measurement and control of different processes must often be transmitted from one location to another. Some of the most common types of signal transmission are listed below.

Mechanical

This type of signal transmission may be in the form of a mechanical link between two points that are quite close together. Common examples are linkages between a damper and a damper drive on a boiler combustion air flow control, or between a pressure sensing element and the pointer on a pressure gage.

Hydraulic

Hydraulic pistons, often actuated by oil or air pressure, are used where an extremely large output force is required. Common examples of their application are found on gas and steam turbine governors.

Pneumatic Signals

Pneumatic instruments use compressed air as a means of signal transmission. The most common signal range is 20 to 100 kPa (3 to 15 psi). This means that the minimum value of the signal is 20 kPa and the maximum is 100 kPa.

The main advantages of pneumatic signals are:

1. The instruments are quite simple and provide trouble-free operation.

2. These instruments may be less expensive than the corresponding electronic instruments.

3. They are safer in operation as there is no risk of electric shock, fire, or hazards due to explosions.

Their disadvantages are:1. The pneumatic signal may not be satisfactory when it must be transmitted over long distances. There is always a lag or delay between the time a change in signal takes place at the transmitting location and the time that the change in signal is sensed at the receiving end.

2. Friction in the pneumatic tubing causes a decrease in the value of the signal as distances become greater (pressure loss in long runs).

3. The cost of tubing for pneumatic signals is greater than for electrical wiring.

4. Ensuring a clean, dry air supply may be costly.

Electrical SignalsElectrical signals may be classified into groups as follows:

1. Voltage Signal

The very common voltage signal is one that operates electrical motor drives. Voltage signals from different sources are applied to sequential control of boilers. If a flame scanner senses a burner flame, it will generate a voltage signal to maintain a fuel valve in an open position. Another example on a boiler is a low-water fuel cutoff. If the water level drops below a preset minimum, a float will close a switch to start a feedwater pump, but if the pump should fail to start, a further drop in level will open the electrical circuit to close the fuel valve.

Certain temperature sensing elements, which will be studied in a later module, generate a voltage when exposed to hot substances.

As with pneumatic signals, transmission of voltage signals over long distance creates problems due to the resistance of the conducting wires.

2. Current Signal

Direct currents have been widely accepted in industry as a means of signal transmission. A series circuit formed by a signal loop will have the same current at the transmitting and receiving ends, even if it is transmitted over long distances. The most common signal range is 4 to 20 milliamperes. When required, dc current signals can easily be converted to a voltage signal by placing a known resistance in the series circuit and measuring the voltage drop across this resistance. The voltage variation across the resistance will be proportional to the current flow, according to Ohm's Law.

In most applications, ac signals are not suitable for remote transmission.

3. Analog Signals

The signals described so far are continuous in nature, as they all have some value between minimum and maximum. For instance, the common pneumatic signal range is 20 to 100 kPa (3 to 15 psi). This means that the usual signal always varies between a minimum of 20 kPa and a maximum of 100 kPa. Under no normal circumstance does the signal decrease to zero. These types of signals are called analog signals.

4. Digital Signals

The opposite of an analog signal is one that is digital, as the value of this signal is either the minimum or maximum value. Digital signals are mostly electrical in nature and can be compared to an electrical relay or switch. When the relay or switch is closed, the output will be at maximum; when the switch is open, output will be zero. This results in a series of pulses. More time and space will be devoted to this form of control in a future module dealing with computer control.

TRANSDUCERS

A transducer is an instrument or device that receives one form of energy and changes or converts it to another form. They are sometimes called converters. Some common types of transducers are:

Current-to-Pneumatic

In many control systems, the transmitters, recorders, and controllers may have current input and output signals, yet the control valve requires a pneumatic signal to open or close. A current-to-air converter or transducer is used to change the current signal into one that is pneumatic.

Pneumatic-to-Current

This type is the opposite to the previous transducer. It accepts a pneumatic signal at the input to the instrument and produces a current signal at the output.

Photoelectric Transducer

This transducer accepts light from some source at the input to the instrument and converts it to an analog or digital system that can be used for control purposes. A fire eye or flame scanner on a boiler is a common example. The burner circuit in a boiler remains energized as long as the flame scanner senses the light from the fire in a boiler. If the flame should go out, the scanner will cause the fuel valve to close immediately.

NON-CONTROL LOOP INSTRUMENTATION

In addition to the types of devices already described in this module, there are many other uses for instrumentation. Sometimes these instruments are also called "controls", but strictly speaking, a control is a special device which maintains a set point, as previously discussed. A process may be equipped with numerous instruments which are not performing control functions at all. Instead, they are used instead to provide:

1. Monitoring of process conditions.

2. Alarms, indicating improper or hazardous operating conditions.

3. Methods of shutting down equipment, especially when operating in unsafe conditions.

4. Remote operation of isolation valves.

5. Logic systems for the proper start up of equipment.

Devices in these types of services have special names, depending on their function. The following is a brief overview of these functions.Indicators

Typical indicators include the familiar temperature, pressure, flow and level gages. There are, however, many other measurements that the operator may need to know in order to properly operate a process. These include valve position, density, composition, dew point, stress, weight, vibration, rotating shaft position, smoke, heat, fire and flame detection, presence of toxic gases, viscosity, pH, conductivity, turbidity, rotational speed and radiation levels.

Indicators may be used to provide a single, local or remote reading, or they may be connected to other devices. In many cases they serve as the sensing element of a control loop.

Switches

Like indicators, switches may be used in special applications or incorporated into control systems. They often act like indicators. There are, for example, high pressure switches and low level switches. In this capacity, a switch will sense a process condition and then initiate a signal to an alarm, shutdown system, or a startup/shutdown logic system. A typical example would be the low water level fuel cut-off switch on an automatically fired boiler.

Switches are often connected into systems, where information is passed from one device to another. The term "relay" is used in this context. A shutdown relay, for example, is a switch which transfers the shutdown signal between two devices, often converting the signal in the process. An example would be a solenoid valve which receives an electric signal and passes it on as a pneumatic signal.

Switches come in many different designs, from actual mechanical devices to computer "bits" and can turn on or off pneumatic, hydraulic, electrical, electronic or digital signals. Instrumentation specialists often use the general term "contact closures" to identify this whole range of devices.

Alarms

Alarms use indicators or switches as sensing elements. They give us a visual and/or audible indication of unsafe or improper operating conditions. They can be displayed on specially lit panels, called annunciators, or on computer terminal screens.

Alarms which are connected on dedicated circuits to specific switches on the equipment are often called "hard wired" alarms. Their alarm points can only be changed by changing the limit points of the switch. Computer based alarms often use process indicators as their source and the alarm points can be changed on the computer screen. These are referred to as "soft" alarms. This gives the operator the flexibility, in special circumstances like startups, to assign the alarms as close to a particular operating point as desired, providing a quick audible indication of problems.

Alarms are sometimes confused with trips or shutdown switches. Although alarms and trips are often connected in shutdown systems, they are separate devices. The alarm, itself, does not shutdown equipment.

Logic Devices

Switches, relays and indicators can be incorporated into automatic "decision-making" systems. These systems may shutdown or start up equipment. An example is the startup system of an automatic boiler, in which the burner ignition equipment (igniter and fuel valves) are operated in accordance with a sequence timer and various interlocks or "permissives", such as air and fuel pressure switches.

Logic systems are also used in batch processing, such as pumping operations where the tanks are filled in sequence. Logic systems can have dedicated wiring, similar to hard wired alarms, or may operate from a computer software using a device called a Programmable Logic Controller or PLC. In processes such as air compression, where pressure, current, and other conditions must be satisfied during the starting sequence, logic systems are often used for sequencing motor starts and stops.

No comments:

Post a Comment