Field Control Station

· High Reliability

- Pair and Spare redundancy

· Input and Computation of Floating-Point Data

· Reduced wiring costs through Remote I/O

· Standard Function Blocks (PID, Seq. Table, Logic Charts, SFC, etc.)

· High capacity due to RISC Processor

· Direct Connection of Subsystems

Application Size of FCS

FCS Optional Software Package

Pair and Spare Redundancy

§ Error detection improvement

§ Bumpless Transfer ( Control Computation is always proceeding on standby side )

§ Memory + ECC

Installation Control Cabinets

Control Signals

· Single Loop Integrity

· Free arrangement of Inputs and Outputs

· Reduction of spare parts

· No signal conditioners required

· Modules configurable from engineering platform

I/O Level Redundancy

· Analog Input: Dedicated Function Block

· Analog Output: Additional Output Card

· Current/Voltage Input

· mV, Thermocouple, RTD Input

· Pulse Input

· Current/Voltage Out

· Field bus (future)

· Voltage Input

· mV Input

· RTD Input

· 2-wire transmitter input

· 4-20 mA Output

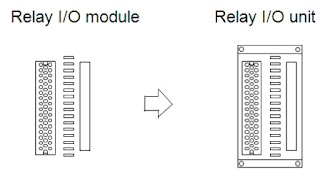

I/O Module (2)

· 16 -pt. Input (isolated)

· 16 -pt Output (isolated)

· 32 -pt. Input

· 32 -pt. Output

· 16 -pt. Input

· 16 -pt. Output

I/O Module (3)

· 16 -pt. Input (isolated)

· 16 -pt Output (isolated)

· 32 -pt. Input

· 32 -pt. Output

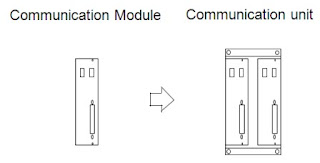

· RS-232C

· RS-422

· RS-485

Engineering

Off line engineering without Target Hardware

Choice of Engineering Environments

Configuration Testing

Control Area, Control Block

· P&ID Compatibility

· Control Block (Max. 4096/FCS)

· Control Drawing (MAx. 255/FCS)

· Control Area (Max.8/FCS)

Control Area’s

· Control function loading, builder operation and test operation can be done on each control area.

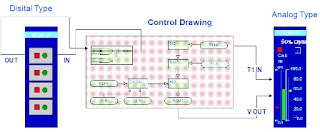

Control Drawing

· Function blocks of regulatory control and sequence control can be on the same drawing

· Free to exchange signal between drawings

· Loop configuration and function blocks can be registered as a module.

· The control drawing can be displayed on the operator station dynamically

Faceplate Block

· Providing a faceplate per compound block control for operators

Internal Data (1)

Ø Feature

· Processed as engineering unit data in system

Ø Purposes

· to process data in standard format (Floating-point format as specified by IEEE754)

· to improve arithmetic precision

· to eliminate normalized numbers

Ø Data flow

· Process Input : Engineering unit conversion data at input module

· Between function block : Engineering unit data transmission and receiving

· Calculation in function block : Engineering unit data

· Process Output : 0-100% data

Internal Data (2)

Function Blocks

Control Block Library

Regulatory Control Block

· Input Processing

· Square root extraction

· Pulse train input

· Digital filter

· Totalizer

· PV overshoot function

· Calibration

· Alarm Processing

Control Block - PID

· Control calculation processing

· Control algorithm (PID)

· Nonlinear gain

· Control output action (velocity type, positional type)

· Direction of control action (positive or negative action switching)

· Reset limiter

· Dead band

· Control Period

· I/O compensation

· Input tracking

· Set point limiter

· Set point pushback

· Bumpless switching

· Initialization manual

· Control hold

· MAN fallback

· AUT fallback

· Computer backup

· Mode conversion interlock

· PRD mode action

Regulatory Control Block - MLD Manual Loader Block

· Output processing

· Output signal conversion

· Output limiter

· Output velocity limiter

· Output tracking

· Output range tracking

· Manipulated output index

· Pulse width output

Regulatory Control Block - Batch Set Block